Hotel Facade Lighting Case Study Using DMX512 Linear Lights

Hotel facade lighting does more than provide illumination — it shapes a hotel’s nocturnal identity, reinforces brand perception, and ensures visual comfort for guests and passersby. For a recent project in China, LNJAMI delivered a tailored solution using DMX512-controlled linear LED fixtures engineered to integrate seamlessly with the building’s architecture. The brief required two non-negotiable outcomes: fixtures that visually blend with the daytime facade rather than appearing as add-ons, and precise optical control to eliminate spill and glare toward adjacent streets.

This case study records the project’s lighting design decisions, product selection, on-site lighting layout and effects, fixture development and manufacturing, and on-site installation and commissioning — all of which combined to produce a refined nighttime landscape without compromising daytime aesthetics or pedestrian comfort.

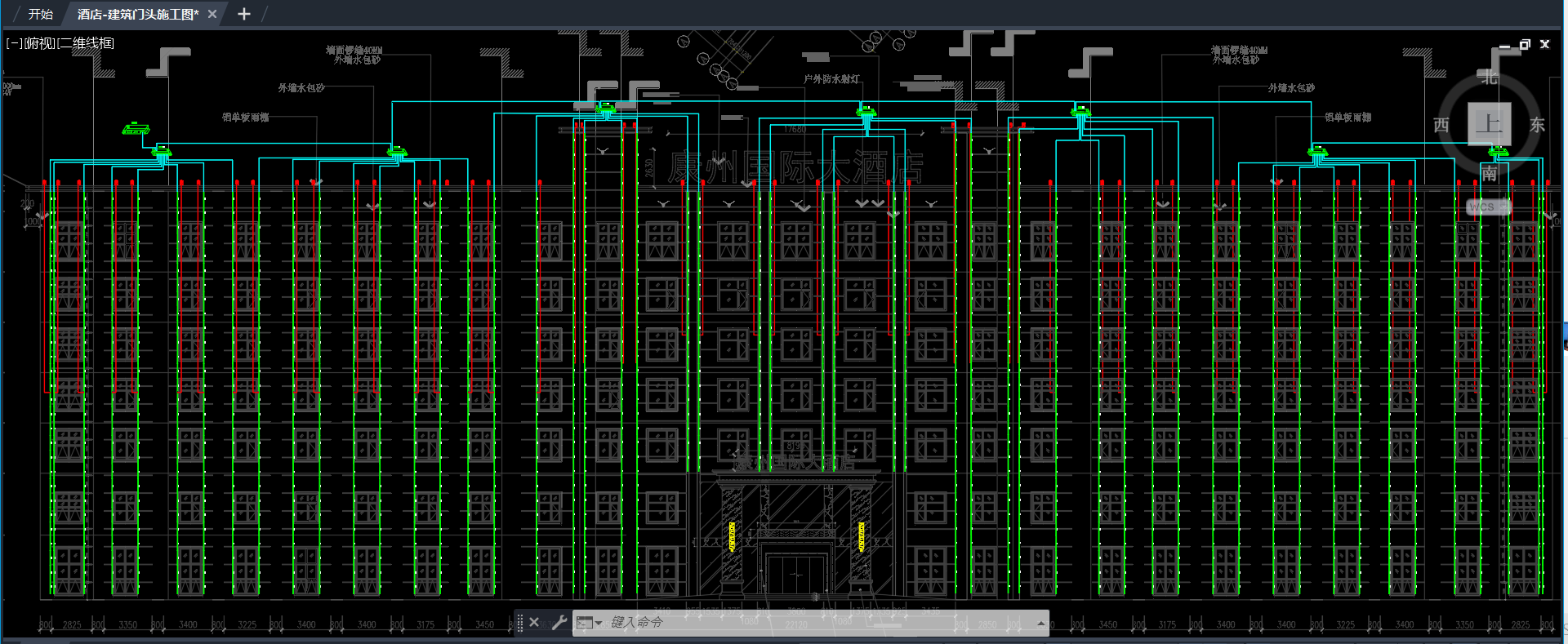

Outdoor Lighting Design Plan

For this hotel facade lighting project, a monochromatic LED wall washer system was used to outline and illuminate the roofline, clearly defining the upper architectural profile of the hotel at night. Across the main facade, multiple vertical linear lights were arranged in alignment with window bays and architectural elements, creating a strong rhythm of vertical light bands and reinforcing the building’s proportions.

Power supplies and DMX512 controllers were centralized at the roof eave level, with all power and control cables routed downward from the rooftop trunk line through vertical shafts or along the exterior facade. To optimize system stability and voltage balance, control signal cables were connected at the top of each vertical linear light run, while power was fed at the mid-point of the fixtures. This configuration improves electrical performance while maintaining clean cable management.

The overall architectural lighting design was intended to emphasize vertical facade lines and the main entrance outline, delivering a clean, well-ordered nighttime appearance with strong visual rhythm. At the same time, careful integration of fixtures ensures that the lighting blends harmoniously with the building materials during the daytime, preserving the hotel’s architectural integrity and avoiding visual disruption.

Key Lighting Challenges

This hotel facade lighting project presented two principal challenges that affected both design intent and technical delivery.

Architectural integration without visual intrusion

The client required that fixtures read as an intrinsic part of the building rather than add-on elements. Off-the-shelf luminaires risked breaking the facade’s material rhythm and proportions through mismatched profiles, visible mounting hardware, or inconsistent color rendering. Beyond aesthetics, any visible fixture outlines or reflections could undermine the refined daytime appearance the client insisted on.

Strict glare and light-spill constraints adjacent to public streets

Because the hotel borders active pedestrian routes and roadways, the owner was highly concerned about direct glare to passersby and outward light spill that could affect neighbors or traffic safety. Uncontrolled light spill would not only reduce pedestrian comfort but also negatively impact the hotel guests' experience and potentially create safety hazards and violate local light pollution regulations.

Custom Product Selection

For this hotel facade lighting project, we selected a custom-designed LED linear light, whose dimensions and control functions met the architectural facade and control requirements.The selected luminaire features a high LED density (48 LEDs per meter), a rated power of 12 watts per meter, an RGBW configuration, and a dedicated warm white channel (3000K). This combination provides both saturated colors for programmable animations and a natural warm white for static architectural scenes—precisely what the client required for their brand promotion sequences and sophisticated environmental lighting.

Height and visual scale

The high LED density creates continuous, smooth vertical light bands when viewed from street level and distance, avoiding visible pixelation on the tall facade.

Dynamic capability

Native DMX512 addressing enables per-run programming and on-site “writing” of animation sequences, meeting the owner’s request for animated scenes during events and promotions.

Optical and spill control

Each fixture is fitted with a dedicated light shield on the same side as the emitter to block unwanted lateral spill. Combined with the fixture’s narrow distribution optics, this greatly reduces glare toward pedestrians and traffic while keeping light focused on the facade plane.

Durability and finish

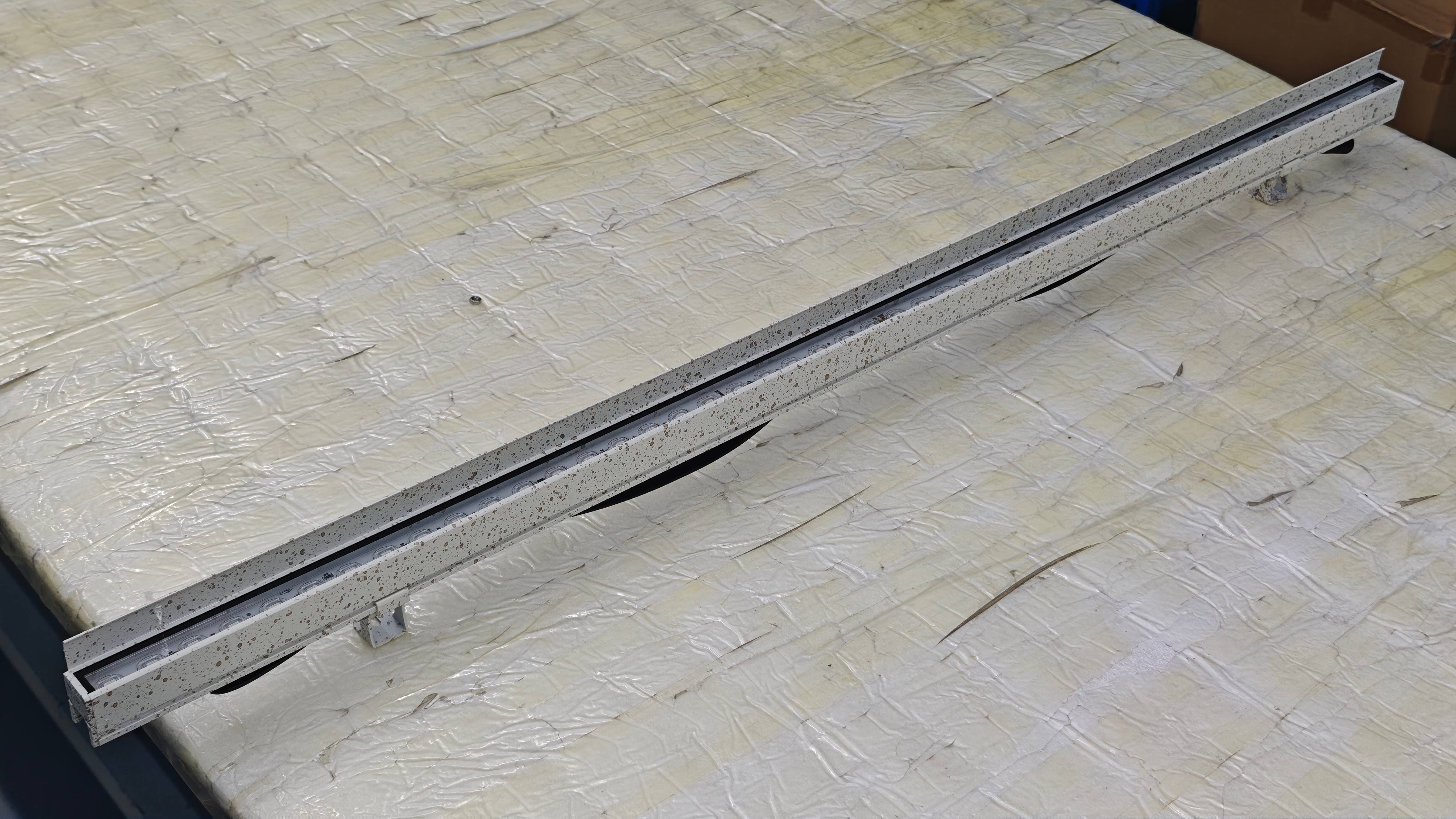

To ensure the luminaires read as an integrated architectural element during daytime, the housings were finished in a custom marble-tone coating that matches the hotel cladding. Fixtures use clear tempered glass as the front cover for robust outdoor protection and stable optical performance over time.

Mounting & aiming

Adjustable-angle brackets were specified to allow precise aiming and alignment along each vertical run, simplifying field aiming and ensuring uniform vertical rhythms even on non-planar surfaces.

Lighting Fixture Production

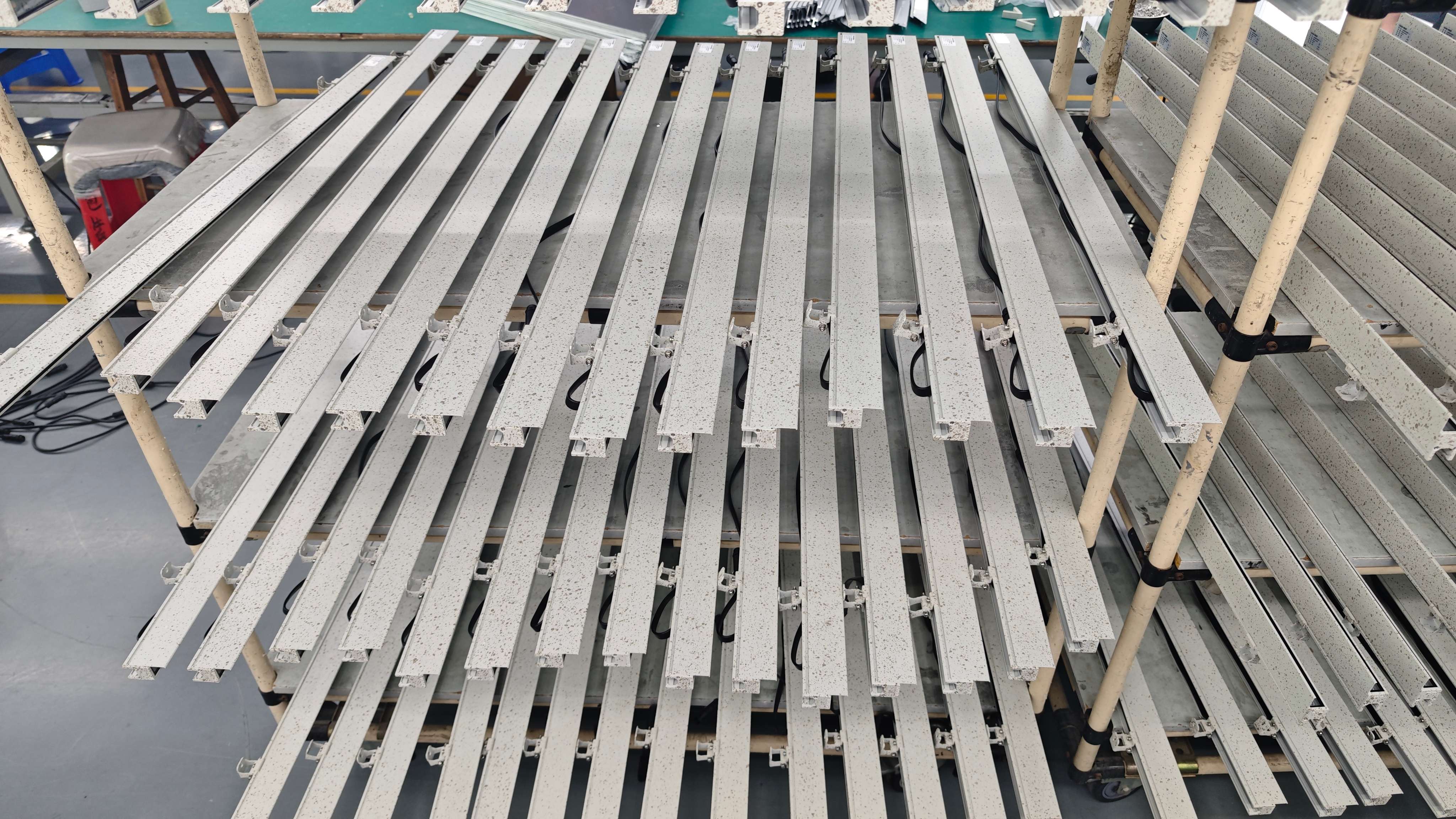

LNJAMI will manufacture the lighting fixtures according to established manufacturing and quality assurance procedures designed for building facade lighting.

During production, the luminaire housings were custom-fabricated to match the facade’s architectural proportions and surface tone. This allowed the fixtures to visually integrate with the building during daytime, avoiding the appearance of added-on lighting equipment. Special attention was given to the profile depth and mounting interface to ensure clean alignment once installed on site.

Regarding optical performance, each fixture is factory-integrated with a dedicated light shield. Before shipment every unit undergoes a 48-hour burn-in and photometric verification to confirm the shield’s spill-control effectiveness, consistent luminous output and color, and overall build quality.

All fixtures were pre-configured for DMX512 control prior to shipment. Addressing was completed or clearly labeled, and each unit underwent power-on testing to verify signal stability and output consistency. We also sequentially numbered every controller and supplied a controller-to-run mapping so the client could install units directly according to the lighting layout. Finally, each luminaire received waterproof sealing and IK impact testing to ensure reliable long-term outdoor operation.

Installation and Control Details

Luminaire installation

Mounting interfaces: Install fixtures on the custom adjustable-angle brackets specified in the drawings. Brackets should be fixed to the prepared substrate with corrosion-resistant fasteners and concealed where possible to preserve daytime appearance.Aim fixtures to maintain consistent vertical alignment along each run. Typical on-site tolerance: maximum 2–3 mm lateral deviation per 3 m run (adjust by project requirement). Use a laser line or plumb line to verify alignment before final tightening.

Controller Installation

According to the design, the DMX512 controllers and main power supply are centrally installed in a hub at the eaves. Each controller is installed in its designated position according to its pre-assigned sequence from the factory.DMX control cables from the controller hub to the top of each vertical run. Use screened/paired cable where required and maintain recommended maximum DMX run lengths or provide DMX repeaters/buffers for long runs. Clearly mark cable entries and junctions on the as-built wiring diagram.

Feed power at the midpoint of long runs and provide additional injection points for very long or high-current runs to prevent voltage drop and color shift. Ensure cable sizing accounts for voltage drop and current-carrying capacity. Implement a single-point grounding strategy for controllers and drivers, and ensure junction boxes, controller enclosures, and serviceable terminations are accessible from the roof or maintenance platforms. Seal cable glands to maintain the IP rating, and include removable covers for future re-aiming or testing.

Commissioning Sequence

Commissioning was carried out in a staged sequence to ensure smooth acceptance and stable long-term operation. Prior to energization, all mechanical fixings, sealing details, cable identification and safety clearances were verified. Upon power-up, mains feeds, driver status indicators and protection devices were checked to confirm normal operation. DMX control signals were then verified at the top of each vertical run using a DMX monitor to ensure correct addressing and reliable response of each fixture.

Static photometric checks were performed with fixtures set to warm white (3000K) to evaluate vertical illuminance and uniformity against design targets. Dynamic scene playback was subsequently tested to validate animation timing, color transitions and overall system behavior. With scenes active, final aiming adjustments were made to eliminate light spill, reduce perceived glare and refine vertical rhythm, after which all brackets were locked. After 30–60 minutes of continuous operation, thermal and electrical stability checks confirmed operation within rated limits, followed by inspection of seals, cable glands and enclosures to verify IP and IK protection before final acceptance.

Conclusion

This hotel facade lighting project demonstrates how carefully engineered lighting — combining custom linear LED fixtures, integrated glare-control optics, and DMX512 addressable control — can transform a building’s nocturnal identity while fully respecting its daytime architecture and the comfort of surrounding pedestrians. The result is a coherent vertical rhythm and a refined nightscape that supports brand expression, enables dynamic programming for events, and meets strict glare and spill constraints.

Key factors behind the successful delivery were early coordination of custom housing and finishes, factory integration of light shields and DMX addressing, a midpoint power-injection strategy to preserve color and output consistency, and a methodical on-site commissioning sequence to validate photometry, aiming and thermal stability. These measures reduced on-site risk, shortened commissioning time, and ensured predictable long-term performance.

If you are planning a similar project, LNJAMI can provide end-to-end support — from concept and product customization to factory QA, DMX programming, and on-site commissioning. Visit our website (ljmlamp.com) or contact our project team to discuss a tailored facade lighting solution for your building.