Tackling DMX512 Transmission Challenges in Large-Scale Outdoor LED Installations

From bridges and skyscrapers to city parks and concert stages, outdoor lighting projects today rely heavily on DMX512 for dynamic, real-time control of LED fixtures. Its flexibility and channel capacity make it a popular choice among lighting designers and system integrators.

Yet as installations stretch across hundreds of meters, DMX512—originally designed for short-range theater systems—faces real limitations. Signal weakening, power drops, and electromagnetic noise can disrupt even the most carefully planned systems.

So what happens when DMX512 networks go long-distance, and how do seasoned engineers keep things stable? This article unpacks the technical realities and field-tested solutions of large outdoor DMX installations.

What Makes Long-Distance DMX512 Unreliable?

DMX512’s underlying protocol, RS-485, works well within moderate distances. But in real-world outdoor environments—subject to weather, power interference, and long cable runs—several issues surface:

1. Signal Loss and Voltage Degradation

As the DMX signal travels along cables, resistance and capacitance gradually distort the waveform. Meanwhile, if power and control run along the same line, voltage can drop significantly at distant fixtures, causing dimming or inconsistent output.

2. Electromagnetic Noise (EMI)

External noise from AC lines, transformers, or even radio towers can infiltrate long cable runs. This interference may cause fixtures to behave erratically or drop offline, especially in humid or high-EMI environments.

3. Device Load and Bus Limitations

RS-485 typically supports up to 32 unit loads per segment, not fixtures per se. Depending on each fixture’s design (some count as multiple loads), the real-world limit may be lower. Exceeding this without signal regeneration leads to instability.

4. Ground Potential Differences & Surges

Long installations across large areas often introduce grounding inconsistencies. These can create voltage differentials between devices, forming loops or exposing controllers to damaging surges, especially during lightning storms.

Practical Solutions That Work in the Field

There’s no silver bullet for long-distance DMX transmission. What works is combining the right strategies based on the environment, project scale, and fixture type. Here are several methods that seasoned integrators use regularly:

1. Signal Regeneration Using Repeaters

To restore signal shape and strength, DMX repeaters are used every 100–200 meters or after 32 unit loads. Unlike passive amplifiers, repeaters regenerate the waveform electrically, ensuring the next segment receives a clean signal. Outdoor models with galvanic isolation and IP65/IP67 ratings are recommended for reliability in rough conditions.

2. Higher Voltage Systems for Longer Runs

Instead of relying on 24V fixtures prone to voltage sag, many projects now adopt 48V DC systems. These reduce current for the same power level, minimizing resistive losses in long runs. High-quality linear lights with low-voltage-drop drivers can sustain 80 meters or more without needing power reinjection midway.

3. Smart Cable Routing and Shielding

Choose shielded twisted pair (STP) cables rated for RS-485, such as Belden 9841. Keep signal cables physically separated from AC power lines to minimize induced interference. Always terminate the last fixture with a 120-ohm resistor to suppress reflections.

Rather than long serial chains, design branching topologies that isolate failure points and make diagnostics easier.

4. Wireless DMX—Use With Caution

Wireless DMX systems are great when physical cabling is impractical—say, over rivers or between moving stage elements. Systems using 2.4GHz frequency-hopping offer decent performance (up to 600 meters line-of-sight), but come with trade-offs:

Latency may rise slightly in congested radio environments

Performance degrades in fog, rain, or high-humidity coastal areas

Requires clear line-of-sight and careful antenna placement

A good practice is to test wireless modules under local environmental conditions before final deployment.

5. Intelligent DMX Chips and Auto-Addressing

Modern DMX driver ICs like SM18522PH or DMX3003 help improve signal reliability by:

Re-shaping incoming signals with internal buffers

Supporting refresh rates up to 4 KHz to eliminate flicker

Allowing auto-addressing, which simplifies installation and avoids human errors from manual DIP switch setup

What About Really Long Distances? Fiber Optics as the Final Answer

For distances beyond 500 meters—or in areas with high EMI—fiber optic transmission is the most robust solution. Using Art-Net or sACN over fiber allows:

Near-zero signal degradation

Complete electrical isolation

Easy integration with standard networking gear (switches, media converters)

Fiber is especially useful for large-scale shows, bridges, or installations crossing electrical grids.

Lessons from the Field: Seaside Promenade Project

On a recent coastal boardwalk project, the team deployed 48V low-drop linear fixtures paired with optical-isolated DMX repeaters. The result?

80 meters of uninterrupted lighting without mid-point power

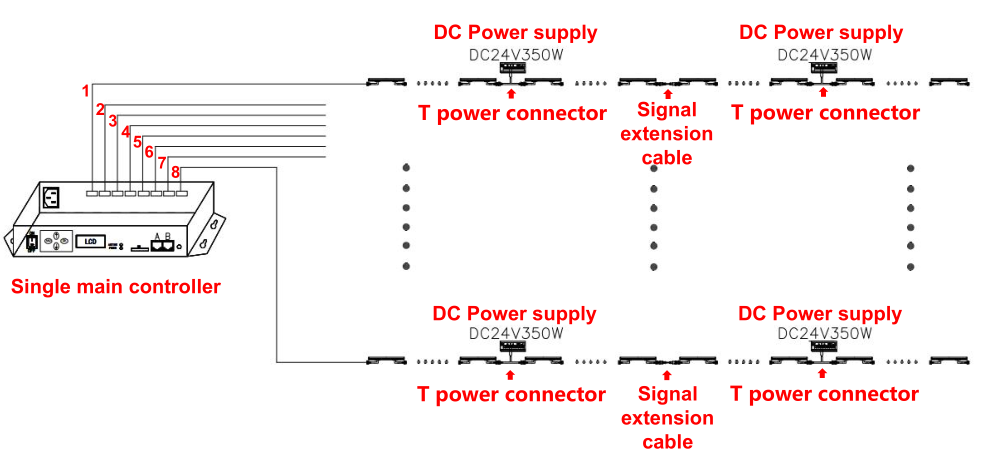

Stable control from a single DMX controller

Reduced materials and labor by over half compared to a traditional setup

The project also included waterproof junction boxes and shielded cabling to protect against salt spray and lightning.

Quick Reference: Engineer’s Checklist

To maintain stable DMX512 signals over long distances, use repeaters every 100–200 meters or after 32 unit loads. These devices regenerate the signal and prevent data loss.

Always choose shielded twisted-pair cables and terminate the final fixture with a 120-ohm resistor. Keep signal cables away from AC power lines to reduce interference.

Use surge protection and optical isolators in outdoor or high-EMI environments to prevent damage from voltage spikes or lightning.

Wireless and fiber options are useful when cabling isn't feasible, but test them first under actual site conditions.

Finally, verify signal quality during setup with tools like oscilloscopes or LED testers to catch issues early.

Final Thoughts: Design with Conditions, Not Just Standards

DMX512 remains a powerful and reliable protocol when used within its physical limitations. But scaling up requires engineering foresight. The best designs consider not just the datasheet—but the landscape, humidity, distance, and fixture behavior.

Whether through smarter wiring, ruggedized components, or segment planning, stable long-distance control is well within reach.

If you're looking for technical guidance or outdoor-ready LED control solutions, consult a trusted supplier or lighting systems expert with real project experience—not just theoretical specs.

LNJAMI — Creating a benchmark solution for long-distance outdoor lighting control

Combining professional engineering practice and product innovation, LNJAMI provides comprehensive and customizable DMX512 solutions for large-scale outdoor LED projects, covering all aspects from technical design to on-site construction and operation and maintenance.

Powerful customization capability: supports deep customization of lamp specifications, colors, power and control methods to meet personalized needs of different scenarios.

High reliability and cost advantage: adopts modular and scalable design, efficiently optimizes wiring and power distribution, saves 70% of costs, and ensures system stability.

IP65–IP68 protection grade DMX linear wall washers and floodlights, adopt high light projection efficiency aluminum profiles, with a service life of ≥50,000 hours, adapting to variable outdoor environments (-20°C ~ 50°C).

Full-process service: From R&D, design to production, project implementation and post-maintenance, one-stop solution to your outdoor DMX lighting challenges.